Sandra Dias

Sandra is the fourth generation of a long line of coopers. She holds a college degree in Chemistry from Universidade de Aveiro and she’s also graduated in Business Management from Universidade Católica. Sandra started working at J. Dias in 1998 and has challenged herself to obtain knowledge and experience in all the departments of the company (management assistant, finance department, sales, logistics and production). With this rock-solid experience she became General Manager of J. Dias in 2006.

sandradias@jdiascooperage.ptAntónio Rodrigues

António, master cooper, is one of our longest-serving teammates. He has started working at J. Dias 38 years ago. He was a boy and he has learned the art from his Father and Grandfather (former workers of this company too). António is responsible for the heat treatment of the barrels and he has big understanding of the effect of each toasting protocol in oak wood.

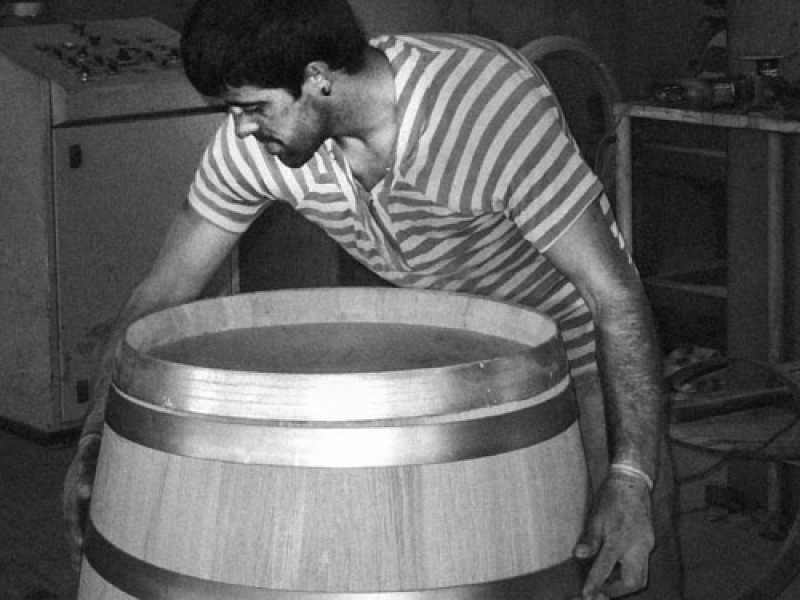

Augusto Félix

Augusto started his career in the cooperage industry before his 20’s at Manuel Alves da Rocha, an old cooperage shop in Paramos. In 2004 he moved to J. Dias. His technical skills, experience and concentration, makes him a precious human resource for the company as well as for his fellow-coopers.

José Lourenço

José worked at Manuel Alves da Rocha, an old cooperage shop in Paramos for around 5 years. However he has started his career in a completely different industry. José has been a tailor assistant for over than 20 years. Probably because of this background he is very perfectionist and always concerned with all the details. José is working at J. Dias since 2005 and due to his technical and human qualities his presence at the cooperage is highly appreciated by everyone.

Aureliano Oliveira

Known as the cooper of “Valinha”, Aureliano was born into a family of independent coopers in Monção. Helping his father since he was a little boy, he slowly learned all the art of barrel making. Later on, Aureliano took care of the business and continued to supply all his father’s regular clients and new ones between the regions of Valença (Portugal) and Ourense (Spain). Aureliano works at J. Dias since 2000 and he is now one of our master coopers. He has great knowledge of wood selection and processing.

Luis Gomes

Drawing his initial experience working as a machine operator in another company in Esmoriz where he worked 14 years, Luis moved to J. Dias in 2000. Luis is responsible for all the barrel laser printing and identification and he supervises all the processes of loading and unloading trucks or shipping containers.

Gisela Costa

Gisela was recruited to J. Dias in 2009 and she holds a degree in Management Assistant. With a solid experience on this, Gisela runs, in addition to those responsibilities, the Logistics department at J. Dias. With great knowledge on inland or overseas shipping processes, she makes sure that all goods leaving J. Dias will get to their destiny promptly and in perfect condition.

Manuel Domingues

Manuel started working at J. Dias when he was on his early 20’s, following the steps on his Father who was also a cooper here. Manuel is a multi-tasked man with plenty of experience in barrel making and machine operating. He’s actually a fine lifttruck driver, extremely valuable for all projects involving big volume vats or foudres, inside the cooperage or abroad.

Mickael Santos

Mickael Santos holds a PhD in Chemistry from the University of Aveiro. In the last years he has been working in the field of wine chemistry (in Portugal and France), mainly on the investigation of maturation effects and oenological treatments on chemical and sensorial properties of wine.

Recruited to J. Dias in 2015, Mickael Santos is the sales manager responsible for the Portuguese and Spanish markets.

Carlos Rocha

Carlos started working at J. Dias in January 2014 and he is the most recent enlisted person of a continuous recruiting program at this company. On his early 20’s, Carlos has a professional degree on woodworking and he did an internship in one of the biggest Portuguese cork producers on the packaging section. Carlos is now operating the leaking test machine, basically controlling the sealing capacity of all our products. Apart from this big responsibility, he’s also on barrel packaging.